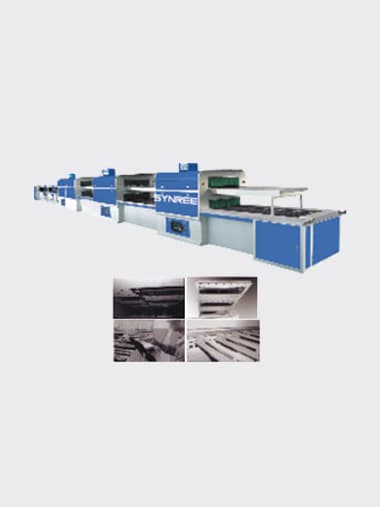

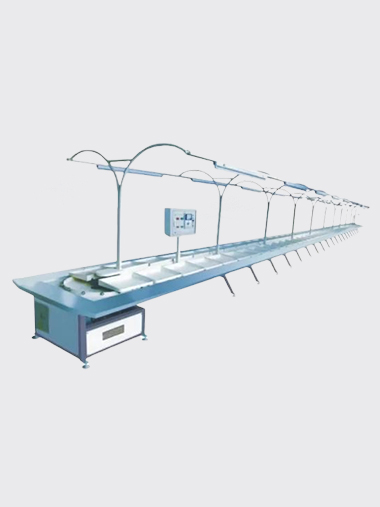

Conveyor

Advanced Double Layer Near Infrared Production Line

SR-969

Features:

- Conveyor adopts two layers: upper and lower layers, the top is enlarged, and the upper is placed on the upper. The oven can control and set the temperature independently according to the different materials. This kind of heating is fast and the efficiency is high. It is 1/3 of the time of conventional electric heating oven, which greatly saves Space and power.

- Oven and brushing unit, equipped with suction and exhaust devices, can effectively eliminate the exhaust gas in the oven to ensure the physical and mental health of employees and meet environmental protection requirements.

- Tri-color warning lights (red, yellow, green) and breakage detection systems can clearly show the work, maintenance, and production status of the machine and have high safety performance.

- Using SCR analog 4-20mA, high-precision temperature control system, so that the temperature and infrared light brightness can be accurately controlled.

- There is a heat-keeping oven attached to the bottom so that the glue molecules on the surface of the shoes can maintain better dynamics and the bottoming effect will be better.

- Adjustable shoe rack for a variety of shoe types.

Parameter:

| Model | SR-969 |

| Dimension{L x W x H) | 1600x140x130cm |

| 1.5m x28 / 2m x1 | |

| Capacity | 800-2000pairs/Shrs/800-2000pairs/8hrs |

| Power | 38kw |

Other Products you may be interested!

Testing Machine

Cutting and Preparation Section Machines

Shoe Machine Manufacture & Supplier

Shoe Machine Manufacture & Supplier

Shoe Machine Manufacture & Supplier

Product Categories

- Foam Machine

- Shoe Machine Manufacture & Supplier

- Conveyor

- Cutting and Preparation Section Machines

- Sewing Section Machines

- Special Sewing machines

- Lasting Section Machines

- Leather Goods Machinery

- Out Sole & DIP Making Machines

- EVA & Rubber Sheet Making Machines

- Rubber Vulcanizing Machines

- Luggage Bag Making Machine

- Others Machines

- Insole & Outsole Preperation

- Printing Section

- Testing Machine

- Spare Parts

- Screw Air Compressor

Contact Us

- Address: No.6 Houjie Daxin Road, Houjie Town, Dongguan City, 523950, China

- Phone: +8618925462765

- Whatsapp/WeChat: +8618925462765

- Email: [email protected], [email protected]