Computer Hydraulic Toe Lasting Machine

Computer Hydraulic Toe Lasting Machine- Home

- Products

- Shoe Machine Manufacture & Supplier

- Computer Hydraulic Toe Lasting Machine

Shoe Machine Manufacture & Supplier

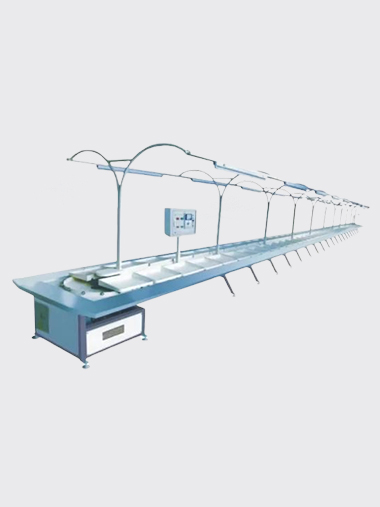

Computer Hydraulic Toe Lasting Machine

The PLC system is equipped with the touch

screen to operate the machine with the graphical

symbols.

The setting of the parameters (time and stroke) is by numerical key in, with the protection of the key switch to avoid the reading or changing by the nonauthorized. Error diagnostic readable on the monitor. Each pincer can be setting with automatic pulling or manual operated, preventing the upper made of different materials is only pulled on one side. After the upper clamping movement of the pincers, it is possible to operate the pincer release and clamp movement manual. The clamping pressure of the pincers can be set with the decompress function during the second time upward movement of the last support. The upward stroke of the last support can be adjusted from the knob outside the machine, and equipped with the position indicator. There are two step upward movement functions for the last support, preventing the slipped of the last when combined with the movement of the heel support. The two segment designed applicator can be used for the quick adjustable width, and also the changeable inner part for the left or right automatically. The toe pusher mechanism is designed with adjustable two step pressure. During the movement of the initial pressure, there are two ways (pressure controlled or position controlled) can be set for the best operation. The forward movement of the wiper can be adjusted.

Specification

| Pincers | 9 |

| Pump Motor | 1.5 kw |

| Max.Power Consumption | 3.7 kw |

| Oil Pressure | 50 kg/cm2 |

| Productivity | 180 pairs/hour |

| Oil Filling | 100 liters |

| N.W. | 1187 kgs |

| G.W. | Be provided before shipment |

| Dimension(LxWxH) | 1800x980x1980 mm |

| Test plate speed | 1920x1000x2170 mm |

Other Products you may be interested!

Product Categories

- Foam Machine

- Shoe Machine Manufacture & Supplier

- Conveyor

- Cutting and Preparation Section Machines

- Sewing Section Machines

- Special Sewing machines

- Lasting Section Machines

- Leather Goods Machinery

- Out Sole & DIP Making Machines

- EVA & Rubber Sheet Making Machines

- Rubber Vulcanizing Machines

- Luggage Bag Making Machine

- Others Machines

- Insole & Outsole Preperation

- Printing Section

- Testing Machine

- Spare Parts

- Screw Air Compressor

Contact Us

- Address: No.6 Houjie Daxin Road, Houjie Town, Dongguan City, 523950, China

- Phone: +8618925462765

- Whatsapp/WeChat: +8618925462765

- Email: [email protected], [email protected]