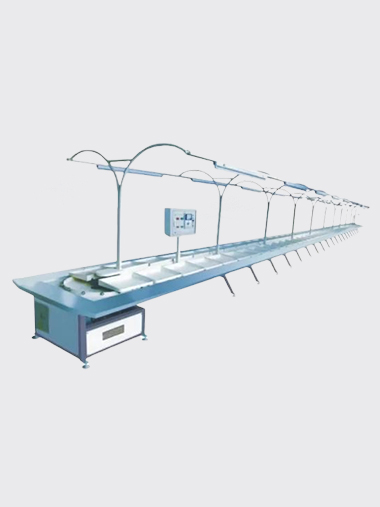

Conveyor

SYSTEMS FOR ASSEMBLY AND FINISHING FOR LASTING LINE

The assembly department in footwear factories is often organized with continuous speed conveyors or manual trolleys, regardless of the type of shoe that is produced. We believe that it is necessary to adapt the systems to organize assembly, based on the customer's production type, with the aim of increasing control, productivity and quality.

This is a motorized chain conveyor, for the assembly and finishing of footwear. The trolleys are positioned equidistant from each other (usually filling the entire conveyor). The speed is continuous and adjustable, in order to establish the production rhythms. The conveyor can be configured from 1 to 4 floors, with the possibility of adjusting the speed of each floor independently, equipping each floor with its own motor. The trolleys are completely customizable, based on the type of processing to be carried out. As optional you can add overhead plants for lighting, air, motive power and automatic heat treatments (humidification, heat setting, glue drying, cold stabilization).

Other Products you may be interested!

Product Categories

- Foam Machine

- Shoe Machine Manufacture & Supplier

- Conveyor

- Cutting and Preparation Section Machines

- Sewing Section Machines

- Special Sewing machines

- Lasting Section Machines

- Leather Goods Machinery

- Out Sole & DIP Making Machines

- EVA & Rubber Sheet Making Machines

- Rubber Vulcanizing Machines

- Luggage Bag Making Machine

- Others Machines

- Insole & Outsole Preperation

- Printing Section

- Testing Machine

- Spare Parts

- Screw Air Compressor

Contact Us

- Address: No.6 Houjie Daxin Road, Houjie Town, Dongguan City, 523950, China

- Phone: +8618925462765

- Whatsapp/WeChat: +8618925462765

- Email: [email protected], [email protected]