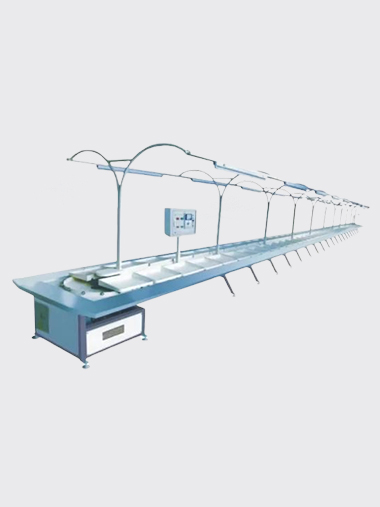

Automatic In-sole Slot Milling / Skiving Machine

Automatic In-sole Slot Milling/Skiving Machine- Home

- Products

- Insole & Outsole Preperation

- Automatic In-sole Slot Milling / Skiving Machine

Insole & Outsole Preperation

Automatic In-sole Slot Milling / Skiving Machine

1.Computer chip automatic control is adopted to make the machine work more stable.

2.Automatic feeding and discharging mechanism makes the groove milling work safe and efficient.

3.High-efficiency automatic dust collecting mechanism ensures that there is no pollution to the environment when the machine is operated.

4.According to insole of different lengths and thicknesses, the length and depth of the milling groove can be adjusted.

5.Discharging insole are stacked neatly.

The machine is a special device for insole shank board slot milling in the shoe-making industry, it carries out groove milling of the shank board according to the requirement of the iron sheet at the position where the shank board and iron sheet are bonded, ensure the shank board and iron sheet are bonded more flatly.

| Model | SR-826 |

| Power of motor | 1.3 kW |

| Milling groove length | 175mm |

| Pump working pressure | 0.5-1.8 MPa |

| Cutter rotation speed: | 3400rpm/mim |

| Package size | 850×620×1280mm |

| Net weight | 248kg |

| Gross weigh | 300kg |

Other Products you may be interested!

Product Categories

- Foam Machine

- Shoe Machine Manufacture & Supplier

- Conveyor

- Cutting and Preparation Section Machines

- Sewing Section Machines

- Special Sewing machines

- Lasting Section Machines

- Leather Goods Machinery

- Out Sole & DIP Making Machines

- EVA & Rubber Sheet Making Machines

- Rubber Vulcanizing Machines

- Luggage Bag Making Machine

- Others Machines

- Insole & Outsole Preperation

- Printing Section

- Testing Machine

- Spare Parts

- Screw Air Compressor

Contact Us

- Address: No.6 Houjie Daxin Road, Houjie Town, Dongguan City, 523950, China

- Phone: +8618925462765

- Whatsapp/WeChat: +8618925462765

- Email: [email protected], [email protected]