Fully-Auto Batch Foaming Machine

Fully-Auto Batch Foaming Machine- Home

- Products

- Foam Machine

- Fully-Auto Batch Foaming Machine

Foam Machine

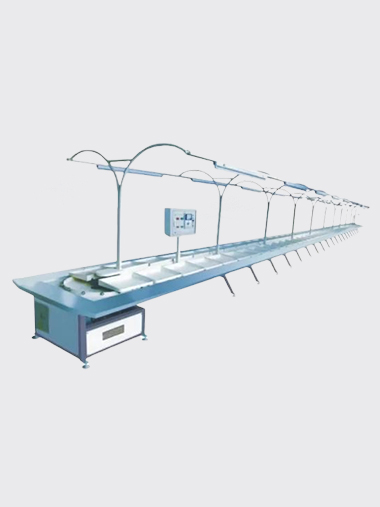

Fully-Auto Batch Foaming Machine

SR-131A

This machine is use to produce 8-50kg/m3 density soft foam, 8 groups chemicals are automatic controlled, use the touch screen control system, user can save 100 different of recipes. Its products used in bed,furniture and all kind sponge producing factories.

Specification

| Mixing Tank Capacity | 180L-250L | Auto Loading & Feeding Pumps For PPG.POP.TDLMC | 4Sets (China Brand) |

| Mixer Total Power | 11KW | Auto Feeding Pumps For Amine Silicone,T-9.H20 | 4Sets (China Brand) |

| Mixing Speed: | 0~2800r/min | Chiller (Both Cooling & Heating System) | Set 10P (Made In Taiwan) |

| Save Formular Q.T.Y. | 6 Groups | Oil Hydraulic System | 1Set |

| Control System | PLC Touch Screen Control System | Electric Float Top System | 1Set (Electric) |

| PPG Tank | 3 Ton*1Set | Air Filtering System | Choose Available |

| POP Tank | 3 Ton*1Set | Foaming Density Range | 8-50kg/Cubicmeter |

| TDI Tank | 2 Ton*1Set | Outputs | 96 Blocks/Per day/Shrs (480m3/day) |

| MC Tank | 1 Ton*1Set | Match with one square Mould Foaming size | 3000mm*3000mm*1200mm(To Be Requested) |

| Silicone Tank | 50L*1Set | Match with one Cylinder Mould Foaming size | Dia 1800mm*H2200mm (To Be Requested) |

| Amine Tank | 50L*1Set | Total Motor Power | Approx 30KW |

| T-9 Tank | 50L*1Set | Machine N.W. | Approx 6Ton |

| H20 Tank | 50L*1Set | Floor Space Required | L10m*W10m*H6m |

| Air Valves | Euro Standard |

Other Products you may be interested!

Testing Machine

Cutting and Preparation Section Machines

Shoe Machine Manufacture & Supplier

Shoe Machine Manufacture & Supplier

Shoe Machine Manufacture & Supplier

Product Categories

- Foam Machine

- Shoe Machine Manufacture & Supplier

- Conveyor

- Cutting and Preparation Section Machines

- Sewing Section Machines

- Special Sewing machines

- Lasting Section Machines

- Leather Goods Machinery

- Out Sole & DIP Making Machines

- EVA & Rubber Sheet Making Machines

- Rubber Vulcanizing Machines

- Luggage Bag Making Machine

- Others Machines

- Insole & Outsole Preperation

- Printing Section

- Testing Machine

- Spare Parts

- Screw Air Compressor

Contact Us

- Address: No.6 Houjie Daxin Road, Houjie Town, Dongguan City, 523950, China

- Phone: +8618925462765

- Whatsapp/WeChat: +8618925462765

- Email: [email protected], [email protected]