Fully-Automatic Continuous Foaming Machine

Fully-Automatic Continuous Foaming Machine- Home

- Products

- Foam Machine

- Fully-Automatic Continuous Foaming Machine

Foam Machine

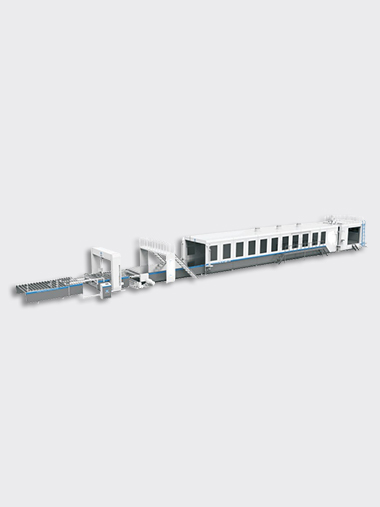

Fully-Automatic Continuous Foaming Machine

This equipment is used in soft PU products. Foaming Density Range: 8-70kg/CBM.The ideal Foam products are involved with Furniture, Shoes, Bra and Electricals field, also suitable for Mattresses, Sofa, Package, Cloths and Car industry. User can save over two hundred different of recipes, To adjust and change them by user at any time.User can remote control it by internet that reduce production cost scientific and directly.PLC Digital Touch Screen or Electric Control System. ----This machine can change the formulation no need stop machine, no need test flow, The degree of resistance to yellow can reach 3-5 international standard, cooperatethe customer's request to offer diffrend formulation, and trainng the foaming engineer. All the P.U. chemicals are first mixed together in a Mixing Head System & then taken into a Metal Trough Or Sprayer where the initial reaction takes place. The rising foam then passes from the Top of the Trough on to a variable width Fall Plate,which then leads the expanding foam block along a metal Slat Conveyor for further expansion.

Specification

| Max. Output Capacity | 200~350kg/min(ContinuousType) | Side Wall Size | L18m*H1220mm |

| Mixer Total Power | 37kw | Fallplate | L7m*W1.2~2.4m(Adjustable) |

| Max. Mixing Speed | 2500~6000r/min | Foaming Platform | L2000mm*W3000mm*H700m |

| Foaming Type | Trough & Sprayer | Conveyor Line | 18m |

| Chemical Groups | 13 Standard Components. | Side/Bottom Paper Feed & Rewind System | 2Sets. |

| Foaming Size | W2300mm*H1200mm (Width Adjustable) | Walkway | W500mm*L6m |

| Control System | PLC Digita Touch Screen Control System | Air Valves | Euro Standard |

| PPG Tank | 5Ton*1Set. | Chiller(Both Cooling & Heating System) | 1Set*20HP(Made In TaiWan) |

| POP Tank | 5Ton*1Set. | Air Compressor | MatchWith7.5KW(10HP)*1Set |

| PPG+CACO3 Tank | 5Ton*1Set. | Side Film Lifting System | 1Set. |

| TDI Tank | 5Ton*1Set. | Foaming Density Range | 8~70kg/CBM. |

| Fire-Retardard Tank | 1Ton 1Set. | Foaming Density Range | 1Set. |

| MC Tank | 1Ton 1Set. | Total Motor Power | Approx 125kw. |

| Silicone +Water+T-9+Amine+Colorx3 Tanks | 150L*7Sets (With Mixing System Except Water) | Machine N.W | Approx 25Ton |

| Silicone +Water+T-9+Amine+Colorx3 Tanks | 1.5Ton 2Set. | Floor Space Required | L48m*W5m*H4.5m. |

Other Products you may be interested!

Product Categories

- Foam Machine

- Shoe Machine Manufacture & Supplier

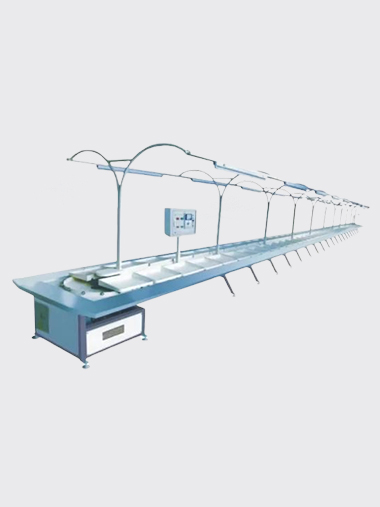

- Conveyor

- Cutting and Preparation Section Machines

- Sewing Section Machines

- Special Sewing machines

- Lasting Section Machines

- Leather Goods Machinery

- Out Sole & DIP Making Machines

- EVA & Rubber Sheet Making Machines

- Rubber Vulcanizing Machines

- Luggage Bag Making Machine

- Others Machines

- Insole & Outsole Preperation

- Printing Section

- Testing Machine

- Spare Parts

- Screw Air Compressor

Contact Us

- Address: No.6 Houjie Daxin Road, Houjie Town, Dongguan City, 523950, China

- Phone: +8618925462765

- Whatsapp/WeChat: +8618925462765

- Email: [email protected], [email protected]