Honeycomb Dehumidifiers

Honeycomb Dehumidifiers- Home

- Products

- Others Machines

- Honeycomb Dehumidifiers

Others Machines

Honeycomb Dehumidifiers

The display screen shows re-producing temperature setting and actual temperature

With high efficiency, XD series honeycomb rotation cylinder dehumidifier is mainly used for

dehumidifying operation on engineering plastic of strong hygroscopic property.

- The dew point of dried wind hit -50°C degree

- Main power switch with mechanical interlock function

- The dehumidification system adopts double cooler structure, can guarantee very low return wind temperature and dew point

Parameters:

| Model | regen.heater power | dry air flow | weight | external size | pipe size |

|

| kw | m³/hr | kg | mm | inch |

| SR-90H | 3.5 | 90 | 156 | 900x520x1700 | 2" |

| SR-120H | 3.5 | 120 | 190 | 900x620x1700 | 2" |

| SR-150H | 4 | 150 | 220 | 1300x700x1700 | 2.5" |

| SR-200H | 5.4 | 200 | 240 | 1300x700x1700 | 2.5" |

| SR-300H | 7.2 | 300 | 260 | 1300x700x1800 | 3" |

| SR-400H | 7.2 | 400 | 380 | 300x700x1800 | 4" |

| SR-500H. | 10 | 500 | 400 | 1500x1000x1900 | 4" |

| SR-700H | 10 | 700 | 410 | 1500x1000x1900 | 4" |

| SR-1000H | 15 | 1000 | 500 | 1500x1200x1900 | 5" |

Humidity and water content rate check list:

| Dew Point | Relative Humidify | Moisture Content | |

|

|

| PPM | % |

| 20 | 100 | 23.072 | 2.307 |

| 10 | 52.50 | 12.117 | 1.212 |

| 0 | 26.10 | 6.027 | 0.603 |

| -10 | 11.20 | 2.574 | 0.257 |

| -20 | 4.40 | 1.025 | 0.103 |

| -30 | 1.60 | 378 | 0.038 |

| -40 | 0.60 | 128 | 0.013 |

| -50 | 0.2 | 39 | 0 |

The body consists of ceramic honeycombs made of ceramic fiber and organic additive, and molecular sieve and silicon glue as basic material crystal sintered by high temperature with surface hard force to be attracted in the inner of honeycombs. So unlikely as general cylinder-type or rotation tray type the powder particles produced by molecular nodes aging to be blown into the drying tube to pollute the plastic, and furthermore its endless using life and washable is unlikely as general molecular bodes to be aging and saturated should be replaced often. The water content will be sucked immediately when the moisture return wind through pass the numerous micro holes of cylinder honeycombs. So they have been dehumidified completely and have been the full dried wind with very low dew point. The principle of re-producing and dehumidification are same and carry out simultaneously, only the reproduced wind blowing has reverse direction.

Dry capability specification:

| raw material | Drying Temperature | Drying Time | Specific Heat | Meterial Proportion | water ratio before dehumidifying | water ratio after dehumidifying | Drying Capacity | ||||||||

|

| C | hr | Kg | kg/dm³ | % | % | Kg/hr | ||||||||

|

|

|

|

|

|

|

| SR-90H | SR-120H | SR-150H | SR-200H | SR-300H | SR-400H | SR-500H | SR-700H | SR-1000H |

| ABS | 80 | 2-3 | 0.34 | 0.6 | 0.3 | 0.02 | 27 | 35 | 71 | 105 | 180 | 210 | 285 | 355 | 425 |

| CA | 75 | 2-3 | 0.5 | 0.5 | 1 | 0.02 | 22 | 30 | 60 | 90 | 150 | 180 | 235 | 295 | 355 |

| CAB | 75 | 2-3 | 0.5 | 0.5 | 0.8 | 0.02 | 22 | 30 | 60 | 90 | 150 | 180 | 235 | 295 | 355 |

| CP | 75 | 2-3 | 0.6 | 0.6 | 1 | 0.02 | 27 | 35 | 71 | 105 | 180 | 210 | 285 | 355 | 425 |

| LCP | 150 | 4 | 0.6 | 0.6 | 0.04 | 0.02 | 20 | 27 | 55 | 80 | 135 | 160 | 210 | 265 | 320 |

| POM | 100 | 2 | 0.35 | 0.6 | 0.2 | 0.02 | 40 | 53 | 105 | 160 | 265 | 320 | 425 | 530 | 640 |

| PMMA | 80 | 3 | 0.35 | 0.65 | 0.5 | 0.02 | 29 | 38 | 77 | 115 | 192 | 230 | 307 | 383 | 460 |

| ILNOMER | 90 | 3-4 | 0.55 | 0.5 | 0.1 | 0.04 | 17 | 22 | 44 | 66 | 111 | 133 | 177 | 220 | 265 |

| PA6/6.6/6.10 75 | 75 | 4-6 | 0.4 | 0.65 | 1 | 0.05 | 14 | 19 | 38 | 58 | 96 | 115 | 153 | 192 | 239 |

| PA11 | 75 | 4-5 | 0.58 | 0.65 | 1 | 0.05 | 17 | 23 | 46 | 69 | 115 | 138 | 184 | 230 | 275 |

| PA12 | 75 | 4-5 | 0.28 | 0.65 | 1 | 0.05 | 17 | 23 | 46 | 69 | 115 | 138 | 184 | 230 | 275 |

| PC | 120 | 2-3 | 0.28 | 0.7 | 0.3 | 0.01 | 31 | 41 | 83 | 124 | 206 | 250 | 330 | 413 | 495 |

| PU | 90 | 2-3 | 0.45 | 0.65 | 0.3 | 0.02 | 29 | 38 | 77 | 115 | 190 | 230 | 307 | 383 | 460 |

| PBT | 130 | 3-4 | 0.3-0.5 | 0.7 | 0.2 | 0.02 | 23 | 31 | 62 | 93 | 155 | 186 | 248 | 310 | 372 |

| PE | 90 | 1 | 0.55 | 0.6 | 0.01 | <0.01 | 80 | 106 | 212 | 318 | 531 | 637 | 850 | 1062 | 1275 |

| PEI | 150 | 3-4 | 0.6 | 0.6 | 0.25 | 0.02 | 20 | 27 | 53 | 80 | 133 | 160 | 212 | 265 | 320 |

| PET | 160 | 4-6 | 0.3-0.5 | 085 | 0.2 | 0.02 | 19 | 25 | 50 | 75 | 125 | 150 | 200 | 250 | 300 |

| PETG | 70 | 3-4 | 0.6 | 0.6 | 0.5 | 0.02 | 20 | 27 | 53 | 80 | 133 | 160 | 212 | 265 | 320 |

| PEN | 170 | 5 | 085 | 085 | 0.1 | 0.05 | 23 | 30 | 60 | 90 | 150 | 180 | 240 | 300 | 360 |

| PES | 150 | 4 | 0.7 | 0.7 | 0.8 | 0.02 | 23 | 30 | 60 | 90 | 150 | 180 | 240 | 300 | 360 |

| PMMA | 80 | 3 | 0.65 | 0.65 | 0.5 | 0.02 | 29 | 38 | 77 | 115 | 190 | 230 | 310 | 385 | 460 |

| PPO | 110 | 1-2 | 0.4 | 0.5 | 0.1 | 0.04 | 33 | 44 | 88 | 133 | 220 | 265 | 355 | 440 | 530 |

| PPS | 150 | 3-4 | 0.6 | 0.6 | 0.1 | 0.02 | 20 | 27 | 53 | 80 | 133 | 160 | 212 | 265 | 320 |

| PI | 120 | 2 | 0.27 | 0.6 | 0.4 | 0.02 | 40 | 53 | 105 | 160 | 265 | 320 | 425 | 530 | 640 |

| PP | 90 | 1 | 0.46 | 0.5 | 0.1 | 0.02 | 66 | 88 | 180 | 265 | 442 | 530 | 710 | 885 | 1060 |

| PS(GP) | 80 | 1 | 0.28 | 0.5 | 0.1 | 0.02 | 66 | 88 | 180 | 265 | 442 | 531 | 708 | 885 | 1062 |

| 345PSU | 120 | 3-4 | 0.31 | 0.65 | 0.3 | 0.02 | 22 | 29 | 60 | 85 | 145 | 173 | 230 | 290 | 345 |

| PVC | 70 | 1-2 | 0.2 | 0.5 | 0.1 | 0.02 | 33 | 44 | 90 | 135 | 220 | 265 | 355 | 442 | 530 |

| SAN (AS) | 80 | 1-2 | 0.32 | 0.5 | 0.1 | 0.05 | 33 | 44 | 90 | 135 | 220 | 265 | 355 | 442 | 530 |

| TPE | 110 | 3 | 0.7 | 0.7 | 0.1 | 0.02 | 30 | 40 | 85 | 125 | 205 | 250 | 330 | 413 | 495 |

Other Products you may be interested!

Product Categories

- Foam Machine

- Shoe Machine Manufacture & Supplier

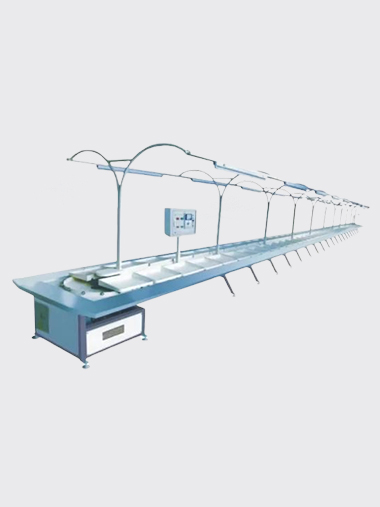

- Conveyor

- Cutting and Preparation Section Machines

- Sewing Section Machines

- Special Sewing machines

- Lasting Section Machines

- Leather Goods Machinery

- Out Sole & DIP Making Machines

- EVA & Rubber Sheet Making Machines

- Rubber Vulcanizing Machines

- Luggage Bag Making Machine

- Others Machines

- Insole & Outsole Preperation

- Printing Section

- Testing Machine

- Spare Parts

- Screw Air Compressor

Contact Us

- Address: No.6 Houjie Daxin Road, Houjie Town, Dongguan City, 523950, China

- Phone: +8618925462765

- Whatsapp/WeChat: +8618925462765

- Email: [email protected], [email protected]