PU Shoe (sole) Pouring Machine (Three Color & Three Density)

PU Shoe (sole) Pouring Machine (Three Color & Three Density)- Home

- Products

- Out Sole & DIP Making Machines

- PU Shoe (sole) Pouring Machine (Three Color & Three Density)

Out Sole & DIP Making Machines

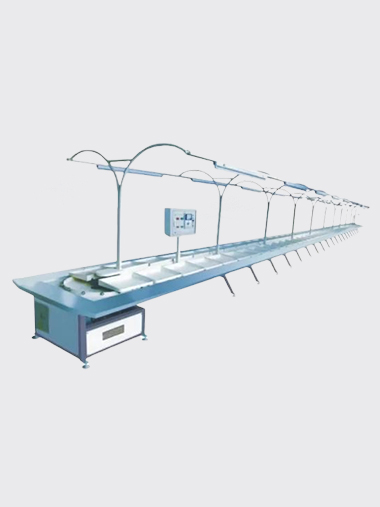

PU Shoe (sole) Pouring Machine (Three Color & Three Density)

sr-880-33

Characteristics:

1. Have two A tank and two B tank, can makedifferent color and different density foaming shoe sole by mixing with A and Braw material.

2. Under different proportion of A and Braw material, can get different properties polyurethane sole material. The mixhead with four needle which can work independently.

3. Heating system with electricity, make heating more fast and more efficientin power saving.

4. Self-developed PLC, with function ofsetting time, real-time monitoring and so on.

5. The speed of metering pump use frequencyconversion control, with advantages of energy saving and keep the rotationalspeed when voltage instability.

Technical Parameter:

| Pouring machine model | JG-880-33 |

| Tank quantity | 4 |

| Tank capacity | 140L |

| Pump quantity | 4 |

| Speed of pump(r/min) | 0---280 |

| Precision (%) | ± 0.5 |

| Max rotating Speed of injection screw | 4500/8600-10000(Choice by yourself) |

| Clean the head | Auto/By hand |

| Voltage | 380V |

| Power | 16(kw) |

| Output | 70(k/s) |

| Clean quantity | 4500(r/min)>25,9000 (r/min)>160 |

| Clean the superfluous material | <25g |

| Product characteristics | Three color three density |

Other Products you may be interested!

Testing Machine

Cutting and Preparation Section Machines

Shoe Machine Manufacture & Supplier

Shoe Machine Manufacture & Supplier

Shoe Machine Manufacture & Supplier

Product Categories

- Foam Machine

- Shoe Machine Manufacture & Supplier

- Conveyor

- Cutting and Preparation Section Machines

- Sewing Section Machines

- Special Sewing machines

- Lasting Section Machines

- Leather Goods Machinery

- Out Sole & DIP Making Machines

- EVA & Rubber Sheet Making Machines

- Rubber Vulcanizing Machines

- Luggage Bag Making Machine

- Others Machines

- Insole & Outsole Preperation

- Printing Section

- Testing Machine

- Spare Parts

- Screw Air Compressor

Contact Us

- Address: No.6 Houjie Daxin Road, Houjie Town, Dongguan City, 523950, China

- Phone: +8618925462765

- Whatsapp/WeChat: +8618925462765

- Email: [email protected], [email protected]