PU/TPU/RU direct injection shoe making machine

PU/TPU/RU direct injection shoe making machine- Home

- Products

- PU Injection Molding Machines

- PU/TPU/RU direct injection shoe making machine

PU Injection Molding Machines

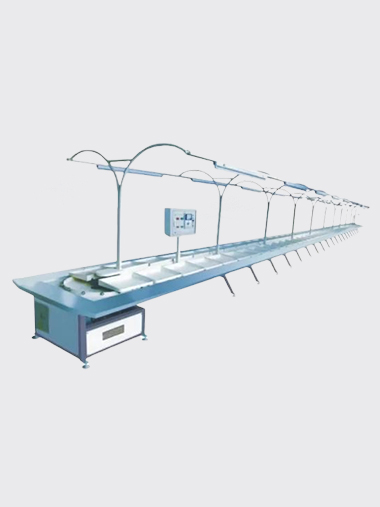

PU/TPU/RU direct injection shoe making machine

PU/PU Double Diret Injection Shoe Making Machine”

1.Injection molding machine for soles and uppers for direct injection of single-density and dual-density PU multi-color on uppers;

2.The PU screw mixing system is resistant to high temperature, low noise and high speed to ensure the best mixing effect.;

3.Wear-resistant, high-precision metering pump adopts high-speed control system to make metering reliable, safe and accurate;

4.Simple and fast injection system increases productivity;

5.All station parameters can be freely programmed;

6.Machine repair service remote control system.

1.Simple operation, reduced labor intensity, high degree of mechanization and automation;

2.The advantages of the injection unit are reflected in the coke burning, air inclusion, density uniformity and the convenience of changing the rubber compound;

3.The mold clamping unit uses imported high-pressure and large-diameter cylinders, which makes the vulcanization quality stable, the output efficiency is high, and the operation is convenient.;

4.Adopt high-speed network (Siemens PROFINET or Beckhoff EtherCAT) control technology, which plays a decisive role in the precision, stability and energy consumption of the machine, making the movement of the mechanism sensitive and rapid;

5.Rexroth pressure-flow proportional control hydraulic system is adopted to make the mechanical action respond quickly, efficiently, stably, and save energy.;

5.All station parameters can be freely programmed;

6.Machine maintenance service remote control system;

6.Adopt PID control heating to ensure uniform and constant temperature of raw materials;

7.Adopt high-resolution displacement measurement system and material quantity measurement system to ensure accurate and stable injection movement and injection dose;

9.Station free programming makes each process simple, intelligent and flexible.

| Model No. | SR-C828/30,D828/30,G828/30 |

| Raw Material | PU |

| MOULD CARRIER | 30 |

| MOULD CLAMPING FORCE | 15KN |

| MOULD SIZE | 320*400(1PAIR)160*400(1/2PAIRS) |

| MOULD HIGHT (SOLE) | 80-200MM |

| SHOE LAST HIGHT (DIRECTLY INJECT) | 333MM |

| PU POURING COMPONENT | |

| POURING DEVICE | 1 SET |

| SCREW DIAMETER | 32MM |

| POURING CAPACITY | 30-100G/SECOND |

| MIXING SCREW SPEED | 4000—10000 R/S |

| RAW MATERIAL COUNTING PUMP | 2SET |

| TYPE OF THE PUMP | GEAR PUMP |

| MATERIAL TROUGH | 2 PCS |

| MATERIAL TROUGH CAPACITY | 251/100 CM³ |

| INSTALL POWER | |

| HOTE PLATE POWER | 0.4*24KW |

| MATERIAL TROUGH HEATING POWER | 2.1-2KW |

| HEATING PIPE | 1.5*2KW |

| POURING HEAD HEATING POWER | l0.33KW |

| MIXING SCREW MOTOR | 3KW |

| FEED MOTOR | 0.55*2KW |

| MIXING MOTOR | 1.1*2 KW |

| PUMP ADJUSTABLE MOTOR | 0.75*2 KW |

| CONDUCTION OIL CIRCULATING PUMP MOTOR | 0.33*2 |

| ELECTRIC PLATE | 2KW |

| TOTAL POWER | 27.6KW |

| PIGMENT SYSTEM (OPOTION) | |

| MATERIAL TROUGH CAPACITY | 30CM |

| MATERIAL TROUGH HEATING | 0.35KW |

| MATERIAL MOTOR BLENDER | 0.18KW |

| PIGMENT SYSTEM SPEED ADJUSTABLE GEAR PUMP MOTOR | 0.37KW |

| AVERAGE ENEGY CONSUMPTION | |

| ELECTRIC ENEGY | 13.5KW/H |

| AIR | 1000MI/MIN |

| FREEZING | 6000FRIG/H |

Other Products you may be interested!

Product Categories

- Foam Machine

- Shoe Machine Manufacture & Supplier

- Conveyor

- Cutting and Preparation Section Machines

- Sewing Section Machines

- Special Sewing machines

- Lasting Section Machines

- Leather Goods Machinery

- Out Sole & DIP Making Machines

- EVA & Rubber Sheet Making Machines

- Rubber Vulcanizing Machines

- Luggage Bag Making Machine

- Others Machines

- Insole & Outsole Preperation

- Printing Section

- Testing Machine

- Spare Parts

- Screw Air Compressor

Contact Us

- Address: No.6 Houjie Daxin Road, Houjie Town, Dongguan City, 523950, China

- Phone: +8618925462765

- Whatsapp/WeChat: +8618925462765

- Email: [email protected], [email protected]