Semi-Auto Batch Foaming Machine

Semi-Auto Batch Foaming Machine- Home

- Products

- Foam Machine

- Semi-Auto Batch Foaming Machine

Foam Machine

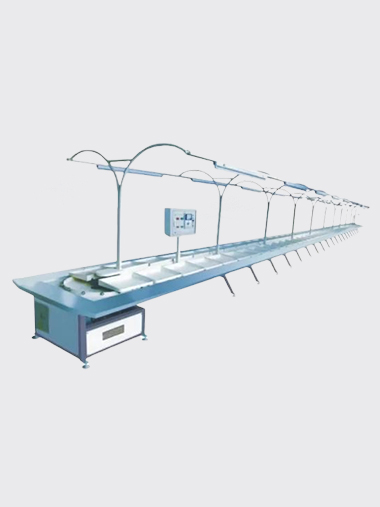

Semi-Auto Batch Foaming Machine

SR-131B

Foam/Sponge producing machine with pneumatic motion, which can be used with Rectangular, Cubic and Cylindrical Molds. The speed of the Mixer can be controlled electronically from control panel. The small Raw-Materials are put in to the Tank manually. Its products used in Bed, Furniture and all kind Sponge Producing Factories.

Specification

| Mixing Tank Capacity | 180L-250L | Chiller(Both Cooling & Heating System): | 1 Set 10P(Made In TaiWan) |

| Mixer Total Power | 11KW | Oil Hydraulic System: | 1Set |

| Mixing Speed: | 0~2800r/min | Electric Float Top System | 1Set(Electric) |

| Save Formular Q.T.Y. | 6 Groups | Air Filtering System: | Choose Available |

| Control System | PLC Touch Screen Control System | Foaming Density Range: | 8~50kg/Cubicmeter |

| PPG Tank | 3 Ton*1Set | Outputs: | 48 Blocks/per day/8hrs(230m3/day) |

| POP Tank | 3 Ton*1Set | Match With One Square Mould, Foaming Size: | L2000mm*W2000mm*H1200mm (To Be Requested) |

| TDI Tank | 2 Ton*1Set | Match With One Cylinder Mould, Foaming Size: | Dia1800mm*H2200mm(To Be Requested) |

| MC Tank | 1 Ton*1Set | Total Motor Power: | Approx 25KW. |

| Air Valves | Euro Standard | Machine N.W | 6 |

| Auto Looding & Feeding Pumps For PPG.POP.TDLMC: | 4Sets (China Brand) | Floor Space Required: | L10m*WI0m*Hóm |

Other Products you may be interested!

Testing Machine

Cutting and Preparation Section Machines

Shoe Machine Manufacture & Supplier

Shoe Machine Manufacture & Supplier

Shoe Machine Manufacture & Supplier

Product Categories

- Foam Machine

- Shoe Machine Manufacture & Supplier

- Conveyor

- Cutting and Preparation Section Machines

- Sewing Section Machines

- Special Sewing machines

- Lasting Section Machines

- Leather Goods Machinery

- Out Sole & DIP Making Machines

- EVA & Rubber Sheet Making Machines

- Rubber Vulcanizing Machines

- Luggage Bag Making Machine

- Others Machines

- Insole & Outsole Preperation

- Printing Section

- Testing Machine

- Spare Parts

- Screw Air Compressor

Contact Us

- Address: No.6 Houjie Daxin Road, Houjie Town, Dongguan City, 523950, China

- Phone: +8618925462765

- Whatsapp/WeChat: +8618925462765

- Email: [email protected], [email protected]